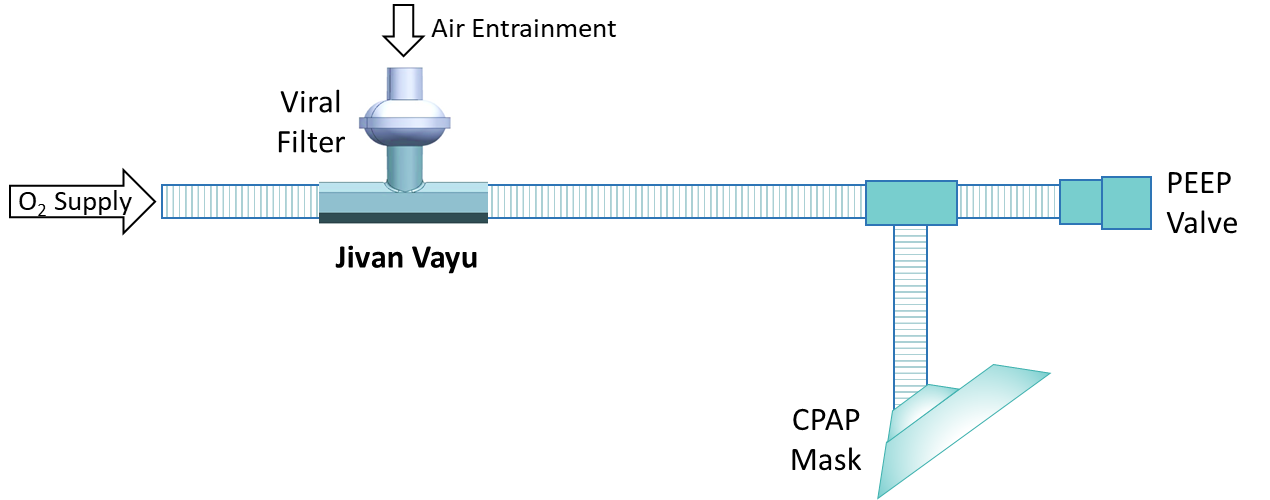

Indian Institute of Technology, Ropar has developed a device ‘Jivan Vayu’ which can be used as a substitute of CPAP machine and functions even without electricity and is adapted to both kinds of oxygen generation units like O2 cylinders and oxygen pipelines in hospitals. These provisions are not available in otherwise existing CPAP machines. The device is ready for medical testing and mass manufacturing.

Continuous Positive Airway Pressure (CPAP) is a treatment method for patients having breathing problems during sleep called sleep apnea. The machine uses mild air pressure to keep the airways open for easy breathing. It is also used to treat infants whose lungs have not fully developed. The machine blows air into the baby’s nose to help inflate his or her lungs. The treatment is all the more necessary during early stages of the Covid-19 infection. It reduces lung damage and allow patients to recover from the inflammatory effects.

Fulfilling all the medically required parameters, this leak-proof, low-cost CPAP delivery system, “Jivan Vayu’ is designed for a 22mm CPAP closed circuit tube. It can even be customized as per the size of the tube. Since it can run during power failures, this can be used to safely transport a patient.

It has an inbuilt viral filter at the air entrainment end which has a viral efficacy of 99.99%”, assures Dr Rakha. The viral filter ensures that the air does not bring in any pathogens from the environment. The device has been manufactured using 3D printing and has also been tested mechanically.

“This was the need of the hour during the present Covid pandemic when power supply is the key concern for saving lives of those on medical equipments such as ventilators and oxygen concentrators”, said Dr. Khushboo Rakha, Assistant Professor, Metallurgical and Materials Engineering, who has developed the device at the Advanced Materials and Design Lab of IIT Ropar.

‘Jivan Vayu’ can deliver high flow oxygen (20–60 LPM) while maintaining a continuous positive pressure of up to 20 cm H2O. The device is designed to maintain an FiO2 of above 40% with a PEEP (positive end-expiratory pressure) of 5-20 cm H2O.

Dr. Khushboo Rakha and her team have collaborated with Mr. Suresh Chand, Faculty Incharge, Rapid Prototyping Lab, Siemens Centre of Excellence at Punjab Engineering College, Chandigarh for 3D printing of the device.